Behind the Science: Why Mirror Polishing Matters

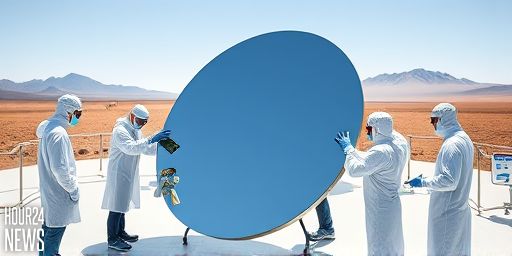

In the dry, pristine skies of Chile’s Atacama Desert, the European Southern Observatory’s Very Large Telescope (VLT) stares into the cosmos with unmatched clarity. The secret isn’t just advanced software or massive detectors; it begins with a single, exquisitely thin layer of metal: the aluminum coating on the telescope’s 25-ton primary mirror. Regular maintenance—cleaning, recoating, and polishing—keeps the VLT at the peak of its performance. This is the story of how precision, patience, and physics come together to reveal the universe in unprecedented detail.

What is Being Polished and Why It Matters

The VLT’s primary mirror is among the largest of its kind. A thin aluminum coating reflects starlight with high efficiency, but even with clean environments, dust, pollutants, and micro-scratches degrade reflectivity over time. In the Atacama’s dry air, fine dust can settle and be abrasive on the coating, reducing the sharpness of images captured by the telescope. To keep the light gathering and image fidelity at their best, technicians regularly recoat and, when necessary, polish the surface. They do not replace the whole mirror at each service; they refresh the coating to maintain the pristine optical surface the telescope requires.

The Process: from Surface to Shine

The maintenance sequence is meticulous. First, the mirror is carefully removed from its mount. Engineers inspect the surface for microscopic particles and irregularities that could scatter light. Next, the old aluminum layer is chemically stripped away in a controlled environment. The surface is then prepared for a new layer—an aluminum coating only about 80 nanometers thick. That ultra-thin film must be uniform at atomic scales to preserve reflectivity across the telescope’s operating wavelengths.

Polishing goes beyond simply applying a new coat. The surface must be exquisitely smooth, free of texture that could blur faint celestial details. Any microscopic imperfection can cast halos around stars, misrepresent the brightness of distant galaxies, or skew measurements of exoplanet atmospheres. Each polishing cycle is guided by precision metrology, using interferometry and other non-contact methods to verify the mirror’s shape and finish. Only when the surface meets exacting standards do technicians re-install the mirror and calibrate the telescope to its optimal state.

Where It Happens: The Atacama’s Silent Workshop

The work occurs at the VLT basecamp at the foot of Cerro Paranal, a site chosen not only for altitude but for the exceptionally dry air and stable atmospheric conditions. The desert setting is a double-edged sword: ideal for astronomical observation, yet challenging for maintenance due to dust and temperature extremes. The technicians’ routines are designed around these constraints, with clean-room practices and controlled handling during each phase of the process. The result is a mirror whose surface remains a nearly perfect mirror of the night sky, enabling the VLT to produce some of the most detailed observations of our universe.

Why It’s So Significant:Science from a Needle’s Width

Consider the capabilities the VLT has unlocked. From imaging distant exoplanets to studying the environments around supermassive black holes, the instrument has expanded our understanding of how galaxies form and evolve. The polish on a single mirror translates into crisper images, better spectral resolution, and more sensitive measurements. In astronomy, where photons are precious and time is limited, every improvement in optical quality counts. The routine upkeep of the primary mirror is a quiet, almost invisible, but essential chapter in the story of modern discovery.

What’s Next for the VLT and its Mirrors

As telescope technology evolves, mirrors may receive even more refined coatings or alternate materials designed to maximize reflectivity across broader wavelength ranges. The VLT team continually evaluates new techniques and protective strategies to extend the life of its optics while maintaining safety and environmental responsibility in one of the world’s most demanding workspaces. The ongoing commitment to precision means that the night sky remains a little closer to our fingertips, even as we push the boundaries of what we can observe.

Want to learn more? The VLT’s ongoing maintenance, scientific achievements, and future plans offer a window into how today’s astronomers convert raw starlight into discoveries that reshape our view of the universe.