What makes a telescope mirror so critical—and so finicky?

In the world of high-precision astronomy, the surface of a telescope mirror is everything. The 25-ton (23 metric tons) primary mirrors of the Very Large Telescope (VLT) are engineered to gather faint starlight and reflect it into sensitive detectors with extraordinary accuracy. Yet just like any finely tuned instrument, they demand constant care. In the bone-dry air of Chile’s Atacama Desert, tiny dust particles, pollutants, and even residual gases gradually settle on the aluminum coating. Over time, this buildup scatters light and dulls sharpness, diminishing the telescope’s ability to resolve fine details in distant galaxies, star-forming regions, and exoplanets.

What is involved in the mirror maintenance process?

Maintaining a huge, delicate optical surface is a multi-step, meticulously planned operation. The routine often begins with a careful cleaning to dislodge surface contaminants. In some cases, technicians use a gentle spray of frozen carbon monoxide across the surface to loosen stubborn dust particles without scratching the coating. The goal is to remove debris without altering the mirror’s precise geometry.

Once the surface is clean, the real work begins: the old aluminum coating is removed so the underlying substrate can be refreshed. The mirror is typically removed from its mount, secured in a controlled environment, and then chemically stripped of the worn layer. A brand-new aluminum coating is deposited in extremely thin layers—often around 80 nanometers thick. To put that in perspective, it’s roughly a thousand times thinner than a human hair. This ultra-thin layer must be perfectly uniform to preserve the mirror’s optical quality across its massive surface.

Where does this take place—and why here?

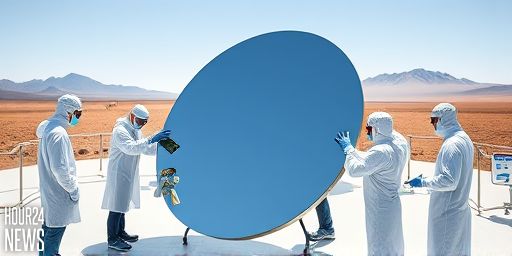

The image and the work happen at the VLT basecamp near Cerro Paranal, perched on the edge of the Atacama Desert. The region’s dry, stable air is ideal for astronomical observations, but it also makes the maintenance environment especially exacting. Even a tiny amount of dust or a stray droplet can compromise the reflective integrity of the surface. Describing the process in person offers a window into the decades of engineering that support modern astronomy—the kind of behind-the-scenes effort that enables groundbreaking discoveries, from tracking exoplanets to studying the environments around supermassive black holes at galactic centers.

Why does recoating and polishing matter?

The L-shaped, star-filled sky of the Southern Hemisphere has rewarded observers with unprecedented views of the cosmos, much of it thanks to the VLT’s mirrors. Fresh coatings maximize reflectivity, reduce light loss, and minimize scattering, all essential for capturing faint celestial signals. The polishing and recoating routine ensures the VLT can continue delivering high-resolution images and spectra that reveal the structure of distant galaxies, the atmospheres of exoplanets, and the dynamics at the centers of active galaxies. These tiny, technical refinements accumulate into big scientific payoffs—enabling astronomers to test theories about the origins of the universe and the physics of extreme environments.

The human side of a high-precision operation

Behind every refreshed mirror is a team of engineers, technicians, and scientists who plan, execute, and verify the process with meticulous records. The operation combines chemistry, materials science, precision engineering, and cleanroom discipline. The result isn’t just a brighter surface; it’s a renewed commitment to measurement accuracy and to the long-term health of one of the world’s most powerful optical instruments.

For observers and enthusiasts, this kind of maintenance is a quiet reminder that astronomy relies as much on maintenance and engineering as it does on curiosity. The VLT’s ongoing work—cleaning, recoating, and polishing—keeps the telescope at the cutting edge, enabling ever sharper views of the universe and helping humanity push the boundaries of what can be observed from Earth.