Reimagining Microactuation with Hydrogels

Researchers are pushing the boundaries of soft robotics by developing micrometer-scale hydrogel actuators that respond to low voltage. Unlike traditional millimetre-scale hydrogels that rely on interfacial pH or osmotic gradients, these new microactuators exploit internal ion migration through nanometer-scale pores. The result is precise, lightweight, and energy-efficient motion at a scale where conventional actuators struggle to perform.

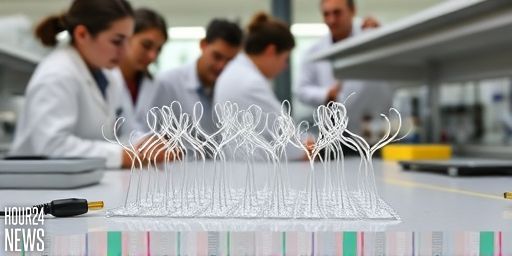

Why 3D Printing Matters for Microactuators

3D printing enables rapid prototyping of complex hydrogel architectures with high fidelity. By precisely controlling pore size, distribution, and network connectivity, engineers can tailor the actuation behavior to specific needs. The micrometre-scale hydrogels produced through advanced additive manufacturing demonstrate repeatable bending, twisting, and curling motions—behaviors analogous to cilia on cellular surfaces but powered by engineered ion transport rather than external chemical gradients.

Internal Ion Migration: The Heart of Low-Voltage Actuation

At the core of these microactuators is the concept of internal ion migration. Nanometer-scale pores permit selective ion movement within the gel, creating local electric-field-driven deformation when a low electrical potential is applied. This mechanism avoids bulky pumps or high voltages, making the devices suitable for compact wearable systems, microfluidic channels, and untethered soft robots. The result is fast, reversible actuation that is gentle on surrounding materials and compatible with bio-friendly operating conditions.

Key Advantages

- Low voltage requirements enable safer, portable operation

- Micrometer scale offers high spatial resolution and precision

- 3D-printed hydrogels allow rapid customization and scalable manufacturing

- Ion-migration actuation minimizes heating and energy waste

Applications in Soft Robotics and Microfluidics

The ciliary hydrogel microactuators have clear implications for soft robotics, where flexible, compliant components help safely manipulate delicate objects. In microfluidics, arrays of these actuators can drive fluidic valves and mixers in compact, low-power devices. Their small footprint and low operating voltage also suit implanted or wearable medical devices that require gentle, controllable motion without aggressive electrical stimuli.

Challenges and Future Directions

While the technology is promising, several hurdles remain. Ensuring long-term durability of the hydrogel network under repeated ion-driven cycles, maintaining consistent actuation in varying environmental conditions, and integrating these actuators with control electronics are active research areas. Future work is likely to explore multi-material printing, smart feedback systems, and scalable manufacturing processes to bring these microactuators from the lab to commercial products.

Concluding Thoughts

The emergence of 3D-printed, low-voltage-driven ciliary hydrogel microactuators marks a significant step in micro-robotics and device engineering. By leveraging internal ion migration through nanoscale pores, engineers can achieve sophisticated, energy-efficient motion at the micron scale, unlocking new possibilities in soft robots, microfluidic control, and bio-integrated systems.