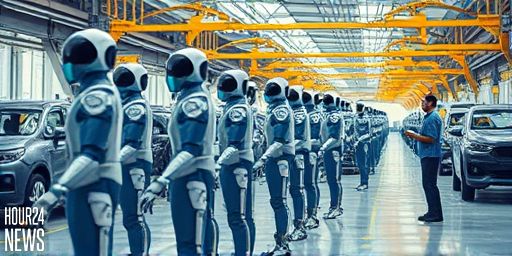

Introduction: A New Era for Auto Manufacturing

The auto industry is sprinting toward a future where humanoid robots, guided by advanced AI, run more of the assembly line. At the forefront is Google Gemini, a system that promises to orchestrate complex robot fleets with precision, speed, and safety. As startups race to build self-driving car software and autonomous tooling, Gemini’s approach could unify perception, planning, and control in a way that scales across factories and vehicle platforms.

How Gemini Is Rewriting Factory Intelligence

Gemini extends Google’s AI backbone into the physical world with a focus on real-time decision making. In humanoid robots that operate on the factory floor, Gemini enables improved collaboration between humans and machines, safer navigation around heavy equipment, and more consistent task execution. The key advantage is a scalable software stack that can adapt to different robot models, payloads, and production lines without reprogramming from scratch.

From Self-Driving Cars to Self-Contained Factory Software

There’s a clear parallel between autonomous driving software and autonomous manufacturing. Startups like HyprLabs are exploring how robust perception, prediction, and control modules can be repurposed for non-vehicle use—specifically, safe robotic manipulation and autonomous task planning on the line. Gemini’s architecture can provide a common language for sensor fusion, decision making, and motion planning, reducing the time to validate new tooling or product variants in a live plant.

Safety First: The Real-World Challenge

When humanoid robots share space with humans, safety is paramount. Gemini’s safety-first design emphasizes redundancy, offline simulation, and on-device fault detection. Plant operators demand predictable behavior: transparent failure modes, clear rollback procedures, and auditable decisions. For startups aiming to deploy on factory floors, this translates to rigorous testing regimes, incident reporting, and industry-standard certifications that align with automotive quality systems.

HyprLabs and the Acceleration of Safe Automation

HyprLabs has signaled an intent to push self-driving software into broader robotics use cases, including industrial automation. By leveraging Gemini’s framework, HyprLabs can unlock rapid iteration cycles—test in simulation, validate in controlled environments, and deploy with confidence on live lines. The result could be shorter lead times for new robotic grippers, tool changers, or cooperative robots (cobots) that work alongside humans without compromising safety or efficiency.

Investment, Competition, and Market Dynamics

The race to automate auto manufacturing is heating up. Large tech platforms bring robust AI, cloud scalability, and a thriving ecosystem of developers, while startups contribute domain-specific hardware insight and faster go-to-market strategies. Gemini’s ability to provide a consistent AI control layer across robot types can attract automakers seeking to standardize operations, reduce maintenance costs, and accelerate digital transformation. Competitors will push back with specialized on-device AI chips and industry partnerships, but a unified platform has clear advantages for plant-wide deployment.

Impact on the Workforce and Skill Shifts

As humanoid robotics become more capable, the workforce experiences both displacement and opportunity. Engineers and technicians will increasingly focus on integrating AI-based control systems with existing production lines, optimizing programming workflows, and ensuring regulatory compliance. Training programs and upskilling will be essential to maximize safety gains and yield improvements while preserving job quality on the factory floor.

What Comes Next

The next wave of factory automation will likely feature tighter integration between perception, planning, and control—an orchestration that enables humanoid robots to adapt to new tasks with minimal retooling. Google Gemini’s entry into this space signals a shift toward platform-based automation, where software updates deliver performance improvements across multiple robot types and industries. For stakeholders in the auto sector, the implication is clear: safer, faster, and more cost-effective manufacturing is within reach if the software stack is solid, transparent, and rigorously tested.