Overview: The Art of Keeping a 25-Ton Mirror Perfect

Night after night in the dry air of Chile’s Atacama Desert, the European Southern Observatory’s (ESO) Very Large Telescope (VLT) relies on its meticulously polished aluminum mirrors to capture some of the most detailed views of the cosmos. The process of maintaining these 25-ton mirrors is a delicate blend of science and precision engineering, ensuring that light is captured with maximum reflectivity and clarity.

Though the VLT’s scientific prowess seems almost magical, it rests on a routine of careful cleaning, recoating, and polishing. Over time, dust, pollutants, and micro-scratches can degrade the surface, reducing reflectivity and image quality. Regular maintenance is essential to preserve the telescope’s ability to trace faint signals from distant worlds and galaxies.

What’s Involved in Mirror Maintenance?

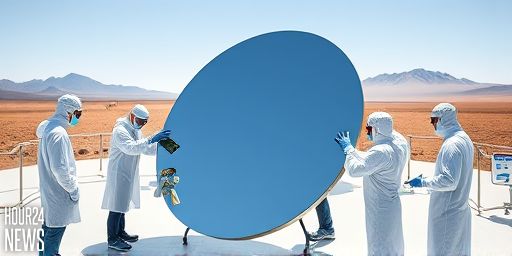

The maintenance workflow begins with a painstaking inspection. The mirror is carefully removed from its mount so engineers can access its surface without introducing contaminants. For light cleaning, technicians sometimes spray frozen carbon monoxide across the surface to dislodge stubborn dust particles efficiently and safely in a controlled environment. This step helps maintain the pristine surface without risking damage to the delicate coating.

When the buildup is more persistent or the coating shows signs of wear, the team will chemically strip away the old aluminum layer. The coating that follows is extraordinarily thin—about 80 nanometers thick, a thickness a thousand times thinner than a human hair. Despite its minuteness, this layer plays a colossal role in determining how much light the telescope can reflect and how accurately it can form sharp images.

After the old coating is removed, the mirror is prepared for a fresh aluminum layer. The new coating must be applied with extreme uniformity to avoid any imperfections that could distort light paths. The result is a mirror surface that reflects as close to perfect as current technology allows, ready to join races against cosmic faintness and resolve details at the edge of the observable universe.

Where Does This Happen?

The operation takes place at the VLT basecamp, nestled at the foot of Cerro Paranal in northern Chile. The desert climate — with its dry air and stable atmosphere — is ideal for astronomical observations, but it also challenges equipment through dust deposition. ESO technicians work in controlled facilities to ensure that the cleaning and recoating steps maintain a level of cleanliness that rivals the best cleanrooms found in universities and industry.

Why Is This Important for Astronomy?

The VLT has delivered some of the most detailed observations of our universe. From imaging exoplanets to studying the environments around supermassive black holes at the centers of galaxies, the VLT has pushed the limits of what ground-based telescopes can achieve. The polishing and recoating of its mirrors are not mere maintenance tasks—they are critical steps enabling high-resolution imaging and precise spectroscopy that drive breakthroughs in astrophysics.

Looking Ahead

Advances in coating technology and surface processing continue to improve mirror reflectivity and durability. Each recoating brings the telescope closer to its theoretical performance, allowing astronomers to glimpse fainter objects, resolve finer details, and test theories about the universe with greater confidence. The VLT’s ongoing maintenance work at Cerro Paranal is a quiet but essential act that keeps the night sky’s secrets within reach for researchers around the world.

Want to Learn More?

Explore ESO’s missions, the VLT’s discoveries, and the fascinating process behind maintaining one of the world’s leading optical observatories.