Turning a stubborn plastic into a valuable feedstock

Waste plastics come in many forms, but not all are easy to recycle. Polystyrene, particularly in its extruded foamed form known as Styrofoam, has long posed a recycling challenge. At Saarland University, a multidisciplinary team led by biotechnologist Christoph Wittmann has turned a stubborn problem into a promising opportunity. Their work demonstrates that polystyrene can be upcycled into high‑value chemical building blocks that feed into the nylon manufacturing chain, offering a route to keep vast amounts of plastic waste within an active material cycle.

A cross‑disciplinary breakthrough in Saarbrücken

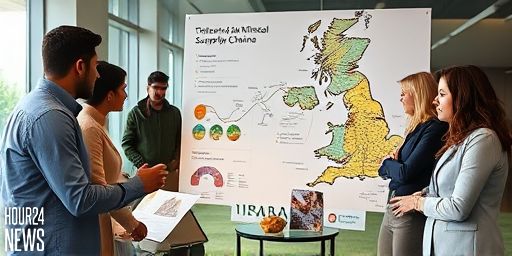

Globally, an estimated 20 million tons of polystyrene waste are generated each year, with only a small fraction recycled. Wittmann and collaborators from Professor Markus Gallei’s polymer chemistry group, the Leibniz Institute for New Materials (INM) in Saarbrücken, and partners in Dortmund and Vienna, have shown that bacteria can metabolize the molecular remnants of polystyrene and convert them into useful chemical products. The paper detailing the discovery appears in the Chemical Engineering Journal and highlights a collaboration that spans biology, chemistry, and materials science.

From waste to microbial feedstock

The process begins by extracting the molecular building blocks from waste polystyrene in an energy‑efficient step. These substrates are then fed to a specialized bacterium, Pseudomonas putida, whose metabolism has been painstakingly tuned in the lab. The aim isn’t to simply break polystyrene down but to steer the bacterium so it yields specific metabolites that can be transformed into nylon precursors. This requires years of optimization to ensure the microbe “consumes” the substrates efficiently and diverts its metabolic pathways toward the desired products.

Nylon precursors: muconic acid as a key relay

A central product of the biological upcycling is muconic acid, a platform chemical that can be chemically converted into adipic acid and hexamethylenediamine—the two primary building blocks of nylon. Each features a six‑carbon backbone with functional groups that make them versatile for polymer synthesis. The researchers emphasize that the polymers derived from recycled polystyrene exhibit properties identical to those made from virgin petroleum feedstocks, a crucial factor for industry adoption and consumer confidence.

Why this matters for the recycling loop

Transforming polystyrene waste into nylon precursors offers a genuine circularity advantage. Rather than downcycling Styrofoam into low‑value products or sending it to landfills, this approach keeps the material within the chemical value chain. In practical terms, millions of tons of polystyrene could be rerouted into high‑quality polymers used in textiles, automotive parts, carpets, and everyday goods—helping reduce the demand for new fossil resources while cutting waste streams.

Collaboration on a campus built for speed

Wittmann notes that the breakthrough was enabled by Saarland University’s compact campus and integrated research infrastructure, which makes cross‑disciplinary collaboration more seamless than in larger, more dispersed institutions. He points to the ease of meeting chemistry colleagues, biologists, and materials scientists for coffee or lunch as a subtle but powerful driver of progress. The project underscores a broader truth in sustainability: progress often hinges on teamwork that spans departments, laboratories, and institutions.

Looking ahead: scale, safety, and industry impact

With the fundamental chemistry established, the next steps involve scaling the process and aligning it with industrial production. Questions of process efficiency, cost, and regulatory approval will guide how quickly this technology can transition from the lab to commercial polystyrene recycling streams. If successful, the method could reshape the feedstock landscape for nylon and related polymers, while offering a model for turning other stubborn plastics into valuable materials through bio‑upcycling.