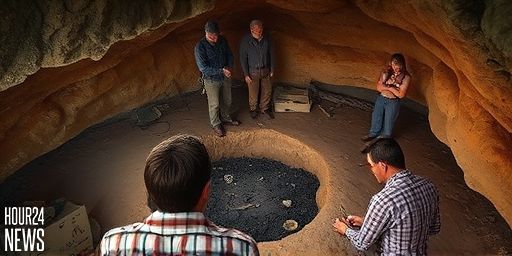

Kvemo Bolnisi: A 3000-Year-Old Copper Workshop Reinterpreted

The Kvemo Bolnisi site in southern Georgia houses a 3,000-year-old metallurgical workshop that has long intrigued archaeologists. When excavations began in the 1950s, piles of hematite (an iron oxide mineral) and slag led researchers to label Kvemo Bolnisi as an early iron-smelting site. New research, however, challenges that interpretation. A fresh reanalysis of the workshop’s metallurgical remains suggests that iron oxide was not the ore being smelted at Kvemo Bolnisi; instead, it functioned as a flux in a copper-smelting process. This shift in understanding offers important clues about how iron metallurgy may have emerged from copper-working traditions.

From Iron Oxide to Flux: The Copper Smelting Case

The core finding is subtle but significant. Copper was extracted using iron oxide as a flux—an additive that helps fluxing and improves yield by managing the furnace chemistry. In other words, the people at Kvemo Bolnisi were deliberately using an iron-containing material, not to smelt iron directly, but to optimize copper production. This reinterpretation relies on modern mineralogical analyses and a careful look at slag composition, revealing a pragmatic experimental mindset among ancient metallurgists.

Iron’s Emergence in the Bronze-to-Iron Transition

Iron is among the most transformative materials in human history, yet its origins are complex. Early iron objects are known from the Bronze Age, including famous pieces from distant civilizations that suggest iron oxide and meteorite iron played a role before smelting became widespread. The breakthrough was the move from ore smelting to extractive iron metallurgy—production from iron ore—that would eventually underpin armor, tools, and infrastructure across civilizations. The Kvemo Bolnisi evidence aligns with a growing view that iron invention could have roots in copper-working communities, where experimentation with iron-bearing materials helped set the stage for later iron smelting.

Interpretive Significance and Expert Insight

Dr. Nathaniel Erb-Satullo, Visiting Fellow in Archaeological Science at Cranfield University, explains the significance: “Iron is the world’s quintessential industrial metal, but the lack of written records, iron’s tendency to rust, and a lack of research on iron production sites has made the search for its origins challenging. That’s what makes this site at Kvemo Bolnisi so exciting. It’s evidence of intentional use of iron in the copper smelting process. That shows that these metalworkers understood iron oxide — the geological compounds that would eventually be used as ore for iron smelting — as a separate material and experimented with its properties within the furnace. Its use here suggests that this kind of experimentation by copper-workers was crucial to development of iron metallurgy.”

He adds, “There’s a beautiful symmetry in this kind of research, in that we can use the techniques of modern geology and materials science to get into the minds of ancient materials scientists. And we can do all this through the analysis of slag — a mundane waste material that looks like lumps of funny-looking rock.”

Support, Publication, and Implications

The Kvemo Bolnisi study, titled Iron in copper metallurgy at the dawn of the Iron Age: Insights on iron invention from a mining and smelting site in the Caucasus, is published in the Journal of Archaeological Science. The research was supported by grants from the British Institute of Ankara, the Gerda Henkel Foundation, and the American Research Institute of the South Caucasus. The findings contribute to a nuanced narrative of the Iron Age: iron was not merely discovered and hammered into existence overnight; it was likely developed through iterative experimentation by copper-smelting communities, using iron-bearing materials to push forward metallurgical capabilities.

What This Means for Our Understanding of the Iron Age

The Kvemo Bolnisi discovery does not rewrite history by negating iron’s transformative impact; rather, it enriches our understanding of how metallurgical knowledge traveled and transformed. It shows that ancient metalworkers were not only masters of copper but also experimental engineers who tested the properties of iron-bearing inputs within existing furnace technologies. In the long arc of history, such cross-pollination—copper-technologists refining techniques that would eventually yield iron—highlights the ingenuity that propelled humanity into the Iron Age and beyond.